Industrial IoT Implementation for Electrical Furnace Monitoring

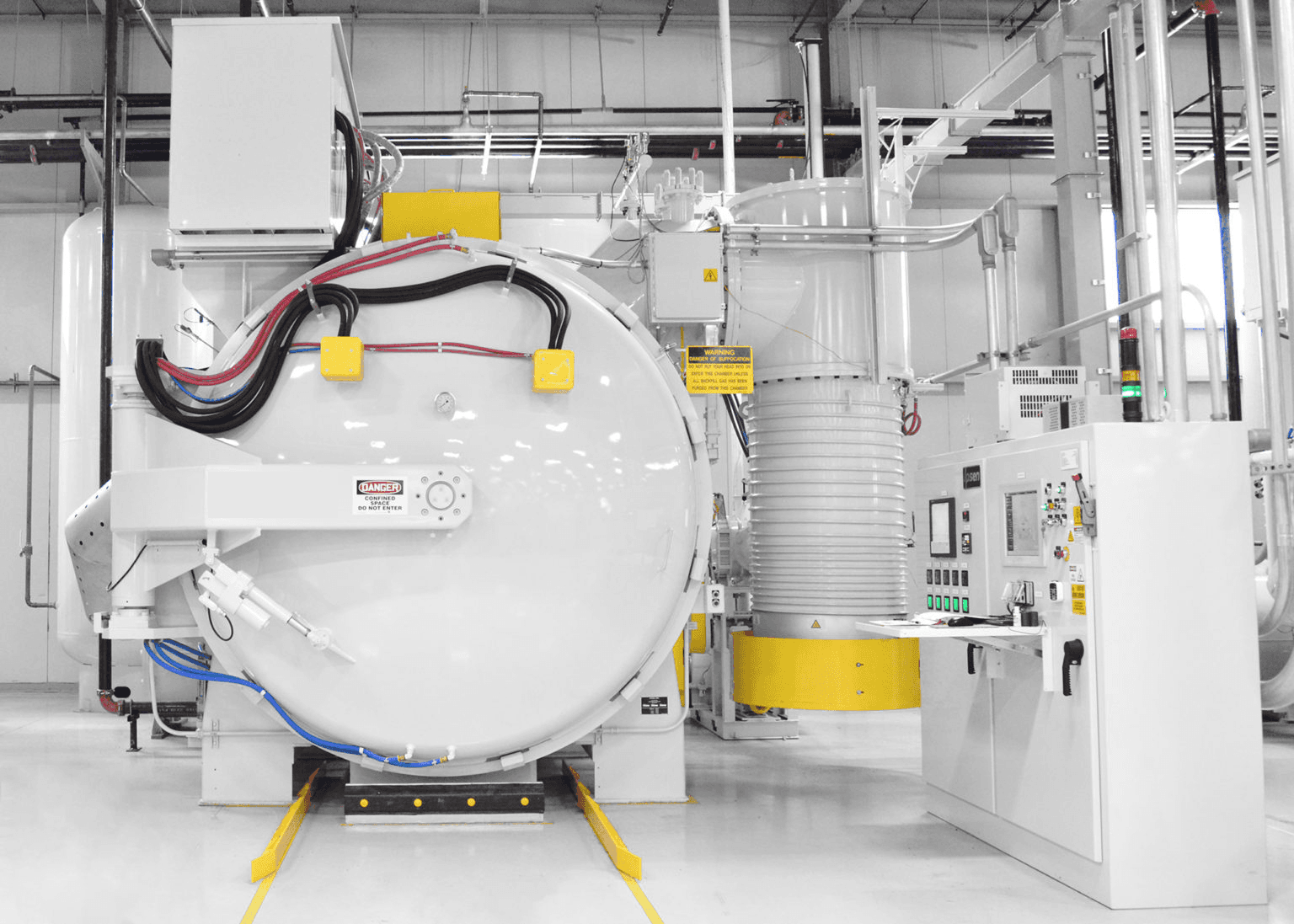

How Blackspektro re-engineered a legacy system into a robust, Azure-powered industrial IoT solution for electrical furnace performance monitoring.

Real-time

Furnace Monitoring

Edge + Cloud

Hybrid Deployment

Client

Confidential (Electrical Furnace Industry)

Industry

Industrial IoT

Solution

Azure-based IoT + Edge System

Tech Stack

Azure • Node.js • Custom Edge Packages

Background

Blackspektro implemented an end-to-end Industrial IoT solution for monitoring electrical furnaces. The project, initially based on PTC ThingWorx, was fully redeveloped using Azure technologies and deployed both at the edge and in the cloud.

Challenges

- Compatibility issues with various edge device manufacturers

- Low or unreliable network bandwidth causing data loss

- Azure IoT Edge compatibility limitations requiring custom D2C scripts

- Need for OTA updates without physical access

Solution

Blackspektro engineered a hybrid system: an edge package for local device handling with caching and OTA capabilities, and a cloud pipeline using Azure IoT Hub and Stream Analytics. An admin dashboard and a customer-facing web app were developed for real-time data access and alerts.

Highlights

- Real-time alerting using custom business logic

- Data caching at the edge to handle connectivity gaps

- OTA deployment system for software and configuration updates

- IAM and RBAC-based secure access model

- Custom-developed microservices for alert handling

Technology Stack

- Azure: IoT Hub, Stream Analytics, Microservices

- Edge: Custom scripts and OTA packages

- Languages: Node.js, Python

Conclusion

The solution empowered the client to move from reactive, manual monitoring to a proactive, automated, and scalable Industrial IoT system. It’s now adaptable to future furnace types and use cases.

USA

+1 (917) 728-1392

16192 Coastal Highway, Lewes,

Delaware 19958

INDIA

Lake Town Rd, Ward 33, Siliguri,

West Bengal – 734007